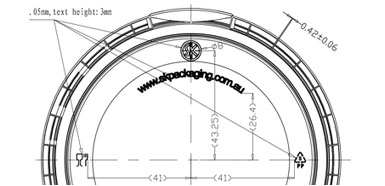

Design

From ideation to Design. We offer a full range of FMCG packaging design services. Create inspirational packaging for your brand that is both functional and attractive, our team can design a tailor-made package solution to satisfy your brief whether it be a tamper-evident, a film-seal container or something completely new

Prototype

Realise your product. Create a custom design that stands out from the competition, amplifies your brand and exudes high-quality in purpose and design. Whether We can scale, shape and print a functional prototype, suitable for marketing and testing purposes, that fully actualises the needs of your product

Production

Mass Produce your product. SK Packaging provides a variety of food packaging products for businesses around Australia. We offer versatility in range, from tamper evident, Film-seal and foil-seal, yoghurt tubs, or containers for soup and sauces. We specialise in producing quality packaging on mass to suit your needs

Plastic Packaging in Australia

At Sneddon & Kingston, we specialise in the design and manufacturing of plastic tubs, containers, buckets and other plastic packaging for both food and chemical businesses. From design to manufacturing, we manage all aspects to make packaging that both suits and elevates your product. Our expertise extends to plastic tubs Australia and food grade plastic containers, ensuring the safety and integrity of your products while meeting stringent quality standards.

Take advantage of the latest innovations and market trends in product development and stay ahead of the competition. For more information about our new product development and design services, contact us. Make SK Packaging your preferred plastic packaging supplier.

We Engineer Your Ideas

Whether it’s in mould labels tubs, food grade plastic containers, tamper-proof containers, plastic food tubs, or any other plastic tubs, we manufacture products that suit your specifications and requirements. In addition, we believe in translating your ideas into commercially successful and viable end products to provide complete customer satisfaction.

Our research team strives continuously to develop new and innovative products that ensure your commercial success. We use a client-centric approach towards developing an innovative packaging solution keeping your need and budget in mind.

Moreover, we also take care of in-mould labels to provide complete integrated facilities to all our clients. Whether it’s label making, mould adaptations or any other services, you can rely on our expertise. In an ever-growing packaging sector, we know in mould labels/IML decoration is the first choice of many clients who want to project the brand image of their products. In addition, our in mould labels decorated thin wall containers are suitable for microwave, deep freezing, and storage.

Obsessed With Quality

Our commitment to product and service excellence is reflected in the growing demand for our products and the increasing customer satisfaction rate. Moreover, we believe that improvement for quality has no finish line; there is always a scope for more. That is why we invest in technology and remain up to date with the latest development to improve ourselves continuously. As a result, our high-speed quality performance and exceptional customer service have enabled us to establish ourselves as a reliable partner of many.

Moreover, we strictly follow Australian standards and norms for plastic packaging to ensure product quality and safety. Quality management, implementation, and product performance are a significant part of our project regardless of your budget and project size.

About Sk Packaging

Get to know our plastic packaging specialists in Preston, Melbourne. Find out why we are preferred choice for rigid plastic food containers Australia. Call us today for more information about our production and distribution capabilities. Find out how we can be your preferred plastic packaging suppliers today.

Over Six Decades of Plastic Packaging Manufacturers Service in Australia

Pioneers in injection moulding, SK Packaging has a proud history of delivering exceptional quality plastic packaging in Australia. Our team draws from a strong foundation of experience and understands precisely what the market is looking for. If you need professional guidance for your next project, speak with us. SK Packaging look forward to partnering with you to be your preferred plastic packaging supplier.

Plastic Packaging for Specific Industries in Australia

Learn more about how we provide plastic packaging for the food and chemical..industries.

See Plastic Packaging Our Products

Browse our selection of tamper evident plastic containers , tubs and other plastic products. For more information about product specifications and custom options,contact us.

Plastic Food Containers for Businesses in Australia and Beyond

Sneddon & Kingston can manage all your injection moulded plastic packaging needs in Australia. We offer everything from tamper evident containers to large scale and customisable branding solutions for FMCG clients. Call today.